On the planet of industrial and industrial cleansing, efficiency and longevity are not just wanted– they are required. The heart of any effective sweeping or scrubbing device is its brush system. Amongst one of the most vital elements are wafer brushes, the workhorses that make contact with the surface and determine the efficiency of the whole operation.

For dealers, agents, and wholesalers, sourcing high-grade, dependable brushes is essential to preserving client satisfaction and securing repeat business. This guide explores the types, applications, and advantages of wafer brushes, highlighting why poly wafer brushes are usually the premium selection and just how a sweeper wafer brush is crafted for peak performance.

What is a Wafer Brush?

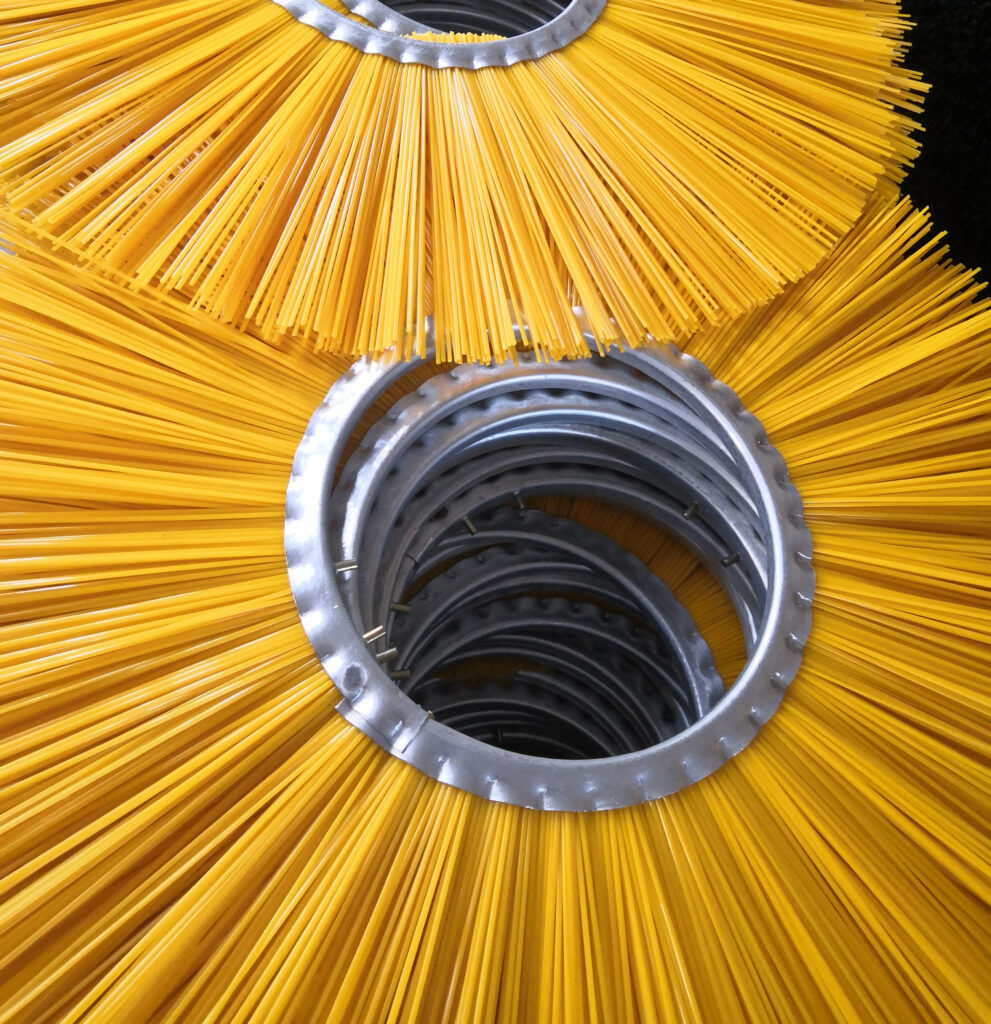

A wafer brush is a kind of disc brush built by piling several round “wafers” or layers of filament material onto a main steel center. This modular design permits amazing adaptability in width, density, and filament type. Unlike standard block brushes, the wafer design gives much more aggressive scrubbing action, much better consistency to irregular surface areas, and much easier substitution of detail areas.

They are mostly utilized in 3 vital areas:

Industrial Floor Sweepers and Scrubbers

Deburring and Surface Area Finishing in Production

Conveyor Belt Cleansing

Why Select Polypropylene (Poly) Wafer Cleans?

When it comes to filament products, not all choices are produced equally. Poly wafer brushes,

made from polypropylene filament, have ended up being the market requirement for lots of dry and damp applications, and a permanent factor:

Chemical Resistance: Polypropylene is extremely resistant to a large range of acids, antacids, and solvents, making these brushes suitable for use in atmospheres where chemical cleansers exist.

Moisture Resistance: Unlike natural fibers, polyfilament will not soak up water, avoiding rot, mold, and the resulting unpleasant smells. This considerably expands the brush’s life span in wet problems.

Abrasion Resistance & Durability: Poly wafer brushes use exceptional wear resistance, giving a long service life, also on rough concrete or abrasive surfaces. This translates to a lower complete cost of ownership for your end-users.

Cost-Effectiveness: They supply a superb balance of efficiency and cost, supplying a premium alternative to more costly abrasive filaments for several tasks.

For wholesalers, equipping poly wafer brushes indicates providing a functional, sturdy, and in-demand item that fits a vast array of consumer demands.

The Engine of Effectiveness: The Sweeper Wafer Brush

The sweeper wafer brush is a details application of this modern technology, developed as the primary brush for commercial sweepers. Its job is to fluster, lift, and straight particles into the hopper. Trick-style considerations for an effective sweeper wafer brush consist of:

Filament Trim Size and Density: This determines the rigidity and aggressiveness of the brush. A shorter trim is stiffer for heavy debris, while a longer trim is extra adaptable for fine dirt on smooth surfaces.

Hub Design: A robust steel hub is essential to avoid warping or failure at high functional rates.

Fixed Dissipation: Several contemporary sweeper wafer brushes are designed with anti-static residential or commercial properties to prevent the accumulation of static electrical energy, which can attract dirt and present a hazard.

A top-notch sweeper wafer brush will dramatically improve a machine’s pick-up performance, lower dust kick-up, and last much longer, decreasing downtime for the operator.

Why Companion with Manybrush as Your Wafer Brush Maker?

As a leading brush producer in China, Manybrush doesn’t simply market items– we give crafted remedies. Below’s why nationwide suppliers and wholesalers choose us as their trusted companion:

Extensive Product Array: From basic poly wafer brushes to custom-designed sweeper wafer brush services, we make everything needed for floor cleaning devices.

Personalization & OEM Solutions: We collaborate with you to develop brushes customized to your specific maker designs or unique applications. Give us samples or specifications, and we will certainly produce to your exact demands.

Rigorous Quality Control: Our items are produced from state-of-the-art products and undergo stringent quality checks to guarantee consistent efficiency and toughness that your customers can rely upon.

Competitive Rates & Quantity Advantages: Our reliable manufacturing processes permit us to supply exceptional value, giving you a healthy margin while continuing to be competitive on the market.

Trustworthy Global Logistics: We are experienced in delivering to dealers and dealers across the country and worldwide, ensuring your orders arrive on time and in the best problem.

All Set to Stock Superior Wafer Brushes?

For distributors, agents, and wholesalers aiming to broaden their product line with top-notch, high-demand commercial brushes, the opportunity is right here. Wafer brushes, especially poly wafer brushes and specialized sweeper wafer brush units, stand for a consistent and successful market.

Let’s review how we can support your organization’s development.

Call Manybrush today for our most current directory, affordable wholesale pricing, and personalized product remedies.

Learn more :