With the continuous rapid development of the social economy, the demand for brushes is also rising. Brush manufacturers’ competition is intense, and the purchase of brushes will also encounter some problems. Let’s introduce the purchase of brushes as follows.

Qualified materials

First of all, it is necessary to learn more about the quality of raw materials. In order to grow, the strip brush manufacturer must have enough professional quality to ensure the quality, conduct business, and withstand the long-term test of the market. It is recommended that students should observe more, research more, analyze more, communicate more, summarize more, and use more often.

Accurate specifications and shape

| Product Specifications | wide of brush holder(mm) | length of brush filaments (mm) | Depth of slit (mm) |

| 15 mm strip brush | 18 mm | 15 mm | 0-15 mm |

| 20 mm strip brush | 18 mm | 20 mm | 0-20 mm |

| 25 mm strip brush | 18 mm | 25 mm | 0-25 mm |

| 35 mm strip brush | 18 mm | 35 mm | 0-35 mm |

| 40 mm strip brush | 18 mm | 40 mm | 0-40 mm |

| 45 mm strip brush | 18 mm | 45 mm | 0-45 mm |

| 50 mm strip brush | 18 mm | 50 mm | 0-50 mm |

| 55 mm strip brush | 18 mm | 55 mm | 0-55 mm |

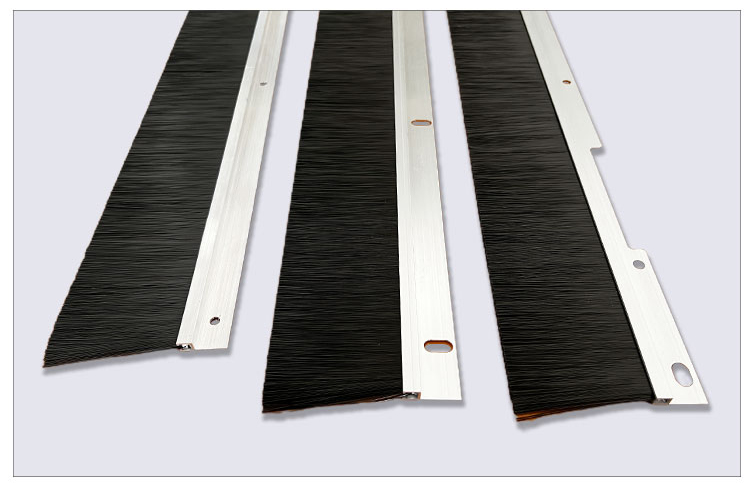

Strip brushes have “T” type、“F” type, and “h” type. Please review our products in detail

brush seals, it is the straight ones that first come to mind. There are, in fact, a lot of other types. The list is almost endless since strip brushes can be made for an exact fit and purpose.

Knowing the strip brush filaments

There are three types of bar brush filaments. These three types are synthetic, metallic, and natural filaments. Some of these synthetic wires can withstand high and low temperatures, do not absorb water. Metal filaments have superior hardness and wear resistance. Natural fibers tend to be the softest. But synthetic filaments are the choice of most strip brushes.

Synthetic filaments include Nylon、Polyester, and Polypropylene.

Metal filaments include Steel, 、Brass, and phosphor bronze

Natural fiber filaments include horsehair and Tampico plant fiber

Application for strip brush

Brush strips for adapting to modern mechanical work are of different specifications. Brushes also exhibit diversity, with applications in various areas, and their functions are also different; there are dust brushes, polishing brushes, cleaning brushes, and other specialized products. There are also differences for the strip brush machine.

- The primary use of the dust brush is installed in the industrial equipment, assembly lines, doors and windows and other parts of the inlet and outlet, used to avoid the dust through these space into, contamination of equipment and products, so the requirements of the brush wire is a high elasticity, smooth brush wire appearance is better, but also has anti-static function.

- Polishing brush is mainly used to deburr and fine polish the appearance of the object, so the different requirements to resolve the species and characteristics of the brush wire, if it is a strong hardness of the steel plate and other need to do the appearance of electroplating polishing, then the aspirational brush wire should be bronze wire, if the general metal material for the appearance of rust and deburring treatment, then the choice of hardness of steel wire can be better.

- Cleaning brush is commonly used industrial roller brush, most of them are used in the deep processing of agricultural and sideline products, fruit and vegetable cleaning and industrial cleaning and dust removal, the requirements of the brush wire to wear resistance, high elasticity and corrosion resistance and aging, long time operation is not easy to deformation, if the brush wire function is not good, when a long time the object in a certain position will constitute a brush roller groove, destroy the function of the roller brush, serious and even constitute the entire brush roller scrap.

Only by understanding the use of brushes, purchasing high-quality materials, and using modern production technology can we make high-quality strip brushes.